StuvEx supplies a large range of products and systems to protect every part of the processing function from fires and explosions. From the raw-product storage silo all the way through to final processing and packing, StuvEx will have it covered. Products that will detect a spark in a fraction of a second, systems which will protect every size of filter from the smallest to the largest. Valves which automatically shut to prevent propagation. Flash, a system that will immediately extinguish an explosion. Along with explosion panels that will safely vent an explosion into the atmosphere and products that will prevent the build-up of static electricity when powder is discharged from road tankers. If you are looking to install a new fire and explosion protection system or modify and improve an existing system, what follows may help.

EXPLOSION VENTING

Explosion venting is about minimising the damage to a vessel or silo by directing the explosion away from people and machinery in a controlled way. Calculating precisely where a vent should be located is the difficult part. Cutting a hole in the side of a vessel and fitting a simple bursting disc without first calculating opening pressures and correct placement could be a disaster in the making. But we do this all the time – and, more to the point, we get it right all the time so please, leave it to us.

We have developed a range of products for Explosion Venting which cover specific requirements:

StuvEx DQS – Flameless Indoor Vent – This is a completely different type of explosion protection system. Once installed, explosive pressure can be safely vented even in areas where the workforce is close to the vent opening. In the event of an explosion, a spring-loaded diaphragm opens and allows the gases to be cooled by a series of metal plates. This stops flames from entering the workplace. When the explosive pressure is reduced, the DQS closes to stop any air re-entering the vessel, stopping any chances of a secondary explosion. DQS is practically maintenance free and ATEX Certified.

The StuvEx Indoorvent has an integrated flame arrestor which allows an explosive event to safely occur inside a building. The Stuvent consists of a large area rupture disc and a flame arresting, ceramic filter. The big advantage of this system is that once activated by an explosion, both the rupture disc and the filter elements can be easily replaced by the user, saving both time and lost production. The Indoorvent is ATEX Certified.

The StuvEx Stuvent Explosion Vent has a thin metal membrane which opens once a specific explosive pressure is reached and it is suitable for areas where both gas and or dust explosions are possible. The membrane is pre-cut on three sides; the fourth side is left un-cut which means that in the event of an explosion the vent stays attached thereby eliminating the damage that a flying metal plate could cause. Four different models are available covering every type of application. Every Stuvent is ATEX certified.

EXPLOSION ISOLATION

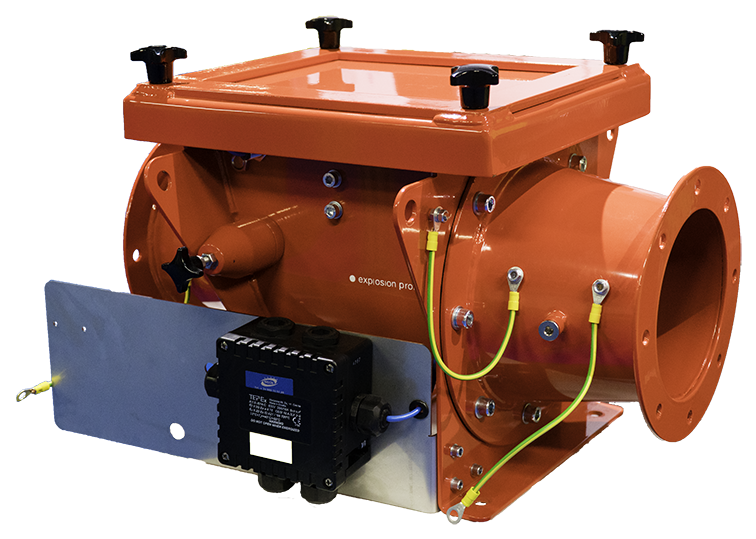

When an explosion occurs, isolating it and stopping its propagation is vital because it has been shown that it is not the first explosion that causes the greatest damage it is the second or subsequent. These additional explosions are inevitably due to non- existent or insufficient explosion isolation systems in place. StuvEx manufactures a range of different valves designed specifically for explosion isolation.

While the NOVEX non-return valve was primarily designed for isolating filters, it can be used elsewhere. A NOVEX valve stays in an open position while air and dust is directed towards the filter. But the moment that reverse pressure occurs due to an explosion, the NOVEX valve closes automatically, which stops the explosive effect travelling back down the line. NOVEX valves are easy to install, are available in a wide range of different sizes and can handle organic and metal dusts. Every model is ATEX Certified.

The Ventex valve is the opposite of the Novex valve in that it was designed to be installed to the exhaust or clean air side of a filter. As soon as the Ventex valve senses the pressure wave preceding a flame jet, it automatically closes. This high-speed valve stops flame propagation and can resist explosive pressures up to 14bar. Every model is ATEX Certified.

The StuvEx FSGV is the fastest way to isolate an explosion with activation times between 8 and 30 m-secs. The FSGV can handle explosive pressures of up to 50 bar. Activation is by means of an explosion detector and it will work in any dry environment regardless of dust levels. There are special versions available for the pharmaceutical industries and every model is ATEX certified.

With a StuvEx Diverter Valve installed in a pneumatic conveying line, an explosion can be diverted to a safe area. StuvEx Diverter Valves are all fitted with position sensors that indicate its position in the line on a factory control system.

Designed to be used in conjunction with a spark detection system, the StuvEx Fire Trap Valve can be supplied with either electro-pneumatic or magnetic release mechanisms.

FLASH EXPLOSION SUPPRESSION

A correctly installed explosion suppression system is one of the best insurances that a processing facility can have. The StuvEx Flash Explosion Suppression System is widely considered to be the industry standard.

The Flash system is both flexible and modular. Explosion detectors triggered by either static pressure or a rate of rise in pressure or optical monitoring, or even a combination of all three send a signal to a multifunctional control unit linked to ultra-fast powder extinguishers filled with food-grade Sodium Bicarbonate. In operation, the detectors continuously monitor the process system being protected. In the event of an increase in pressure or optical detection a signal is sent to the control unit which, in turn, triggers the gas generators of the extinguishing agent bottles. It takes milliseconds to flood the area with enough Sodium Bicarbonate to suppress the explosion before it has had a chance to take hold. As sodium bicarbonate is used as the suppressing agent cleaning is easy. While other manufacturers use pressure vessels in their systems, which can leak, the Flash system is powered by gas generators, so no re-pressurising is need.

EARTHING CONTROL

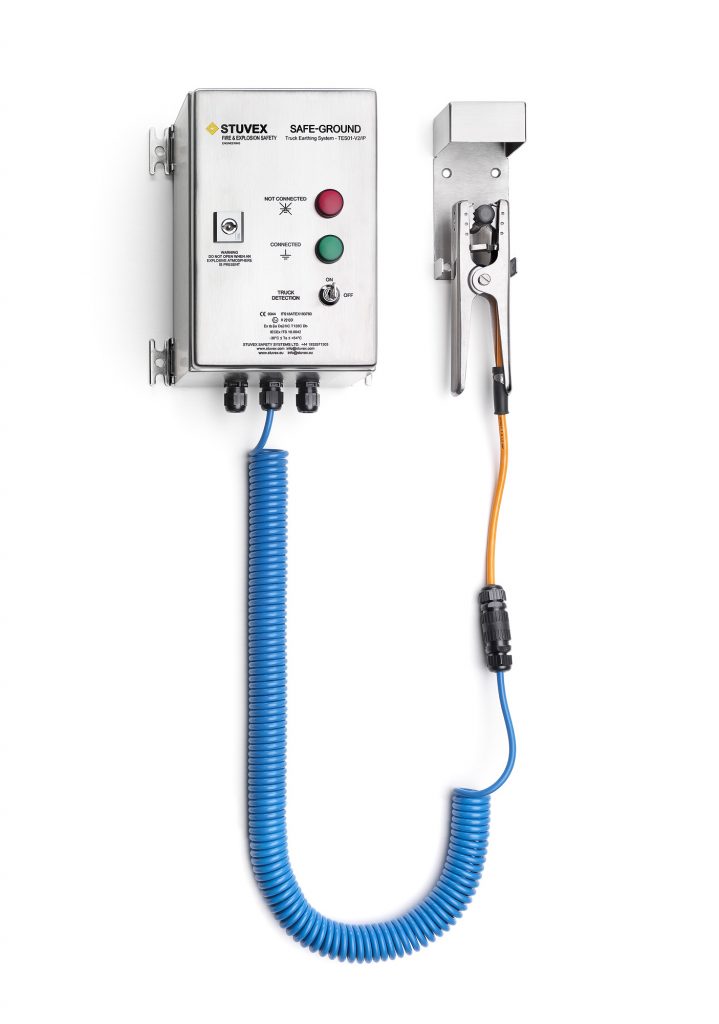

Since its launch, StuvEX has sold hundreds of its market leading Safeground Earthing Systems throughout Europe and has been at the forefront, dealing with the dangers of static electricity in the transport and process industries. StuvEx manufactures two types: One for dusts and the other for gas.

Safeground consists of an easy to install Control Unit, a cable, and an earth clamp. Both types will only allow the object – a road tanker for example – to be discharged if it safely earthed. If it is safely earthed, a green light will show on the Control Unit. A poor earth and a red light will show, the latest dust versions now feature a stainless-steel casing for easy cleaning and maintenance and a revised facia. Safeground has dual certification – ATEX and IECEx.

FILTER PROTECTION

StuvEx has a solution to the problem of fires in process filters which is based on their CO2 fire extinguishing system which can be installed on a new filter or retrofitted to an existing filter.

The StuvEx Filter Protection system uses spark detectors and/or heat sensors on the filter to trigger the control unit. The control unit provides an audible alarm and operates a relay interlock to shut down the filter and associated process equipment. After a short delay for evacuation, a solenoid valve is activated, flooding CO2 through pipework to injection points located on the filter.

The StuvEx CO2 fire extinguishing system is simple to install. A single cabinet houses both the control system and the CO2 bottle assembly, which features a weighing system to ensure that it is full.

Product Development is a key phrase at StuvEx. Technology does not stand still and neither has StuvEx. The development of products that will stop explosions and fires occurring and make the process industries safer is what StuvEx is all about so before upgrading or renewing your factories fire and explosion safety systems, speak to StuvEx first.