CR39 verses polycarbonate lenses

With 1 in 4 people requiring prescription eyewear, choosing the right provider for your safety prescription glasses is key. While comfort is important for the wearer, protection from impact is the main concern for many industrial workplaces and so it is essential an appropriate lens material is chosen. The choice of safety glasses should ensure all colleagues are receiving the same level of protection, prescription lenses or not.

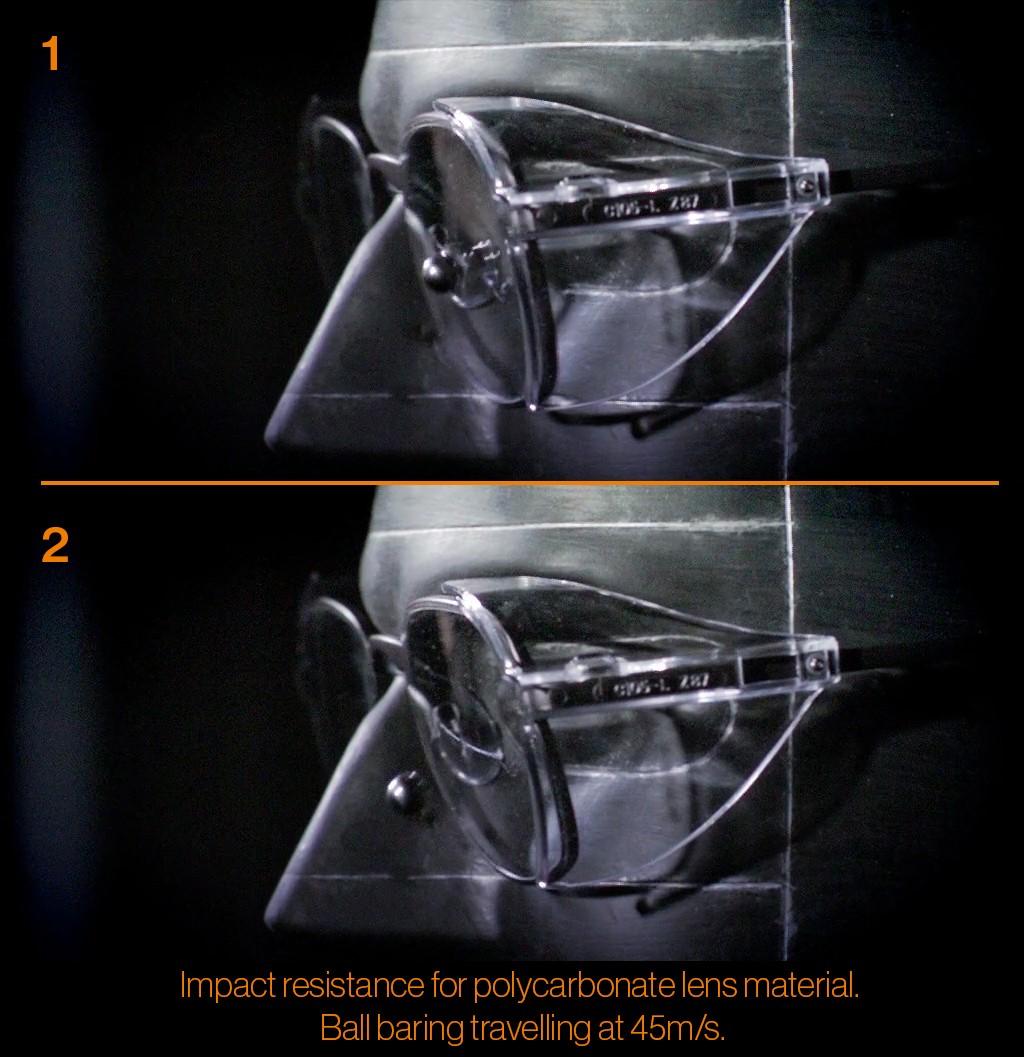

uvex provide a choice of metal, plastic and wraparound frame styles in single vision, bi-focal or varifocal lenses. These lenses are manufactured from polycarbonate, originally developed for the aerospace industry for its exceptional impact resistance. Polycarbonate lenses conform to EN166F and are thinner and lighter than other materials, and naturally block out 100% of the sun’s UV rays.

Polycarbonate is inherently soft allowing it to absorb impacts, ideal for safety eyewear. Due to this softness however, a hard coating must be applied, as a minimum, to the outside of the lens helping to protect it and avoid scratching.

An alternative material to polycarbonate is CR39, a plastic polymer commonly used in the manufacture of eyeglass lenses. Unlike polycarbonate, CR39 requires a UV coating to be added to protect eyes from the sun’s harmful rays. A UV filter is extremely important, especially if you or your employees work outside.

Although commonly used by high street opticians in prescription safety eyewear, CR39 only offers increased robustness conforming to EN166S similar to that of toughened glass. Many high street prescription safety lens ranges start with CR39 and only ‘upgrade’ to polycarbonate upon request. This is not common knowledge and many wearers assume they are protected just like their peers.

It is important to note that CR39 is ideal for everyday glasses and Visual Display Users (VDU) but it’s not suitable for workplaces where impact poses a risk.

For uvex safety is paramount. Ensure your prescription safety glasses will perform should the unthinkable happen by checking the lens on your glasses to see what markings it has. This information will be either at the top of the lens or on the side. Look for the letters S or F; if you can see an S your glasses are likely to be CR39.

Our top tips:

- Establish the requirements of the prescription wearer and the hazards they are exposed to

- High street prescription safety offers often start with CR39 and only ‘upgrade’ to polycarbonate upon request

- If you buy from a high street optician don’t assume the glasses have the same impact protection as safety eyewear users

- Ensure you explain to the optician the hazards you are exposed to at work

- Ensure you know which lens material your glasses will be made from